Description

Sound resistance for doors refers to the ability that a closed door has to attenuate incoming noise within a space. To acoustically isolate the rooms and eliminate both external and internal noise, the ideal solution is soundproof doors.

Key Issues:

Doors are a weak link in terms of sound and can reduce the acoustical performance of the wall. The use of Acoustic doors can improve the sound isolation between spaces in a residence or even stop the noises originating from the external environment from making its way in, whilst providing added thermal control.

Noise and Attenuation:

When selecting a door for noise attenuation, you should take into account the sounds that emerge between the spaces in a residence. For effective noise attenuation the door has to be properly manufactured and insulated. In general the sound producing qualities depend on the composition of the door and the sealing of the surrounding areas, where the sound can penetrate.

Acoustic Seal:

Our door systems, feature a unique twin compression acoustic seal on either side of the frame – engineered between the door and the frame it protects the door from damage during closing and cushions it to reduce wear and tear of the door. These sealing rubbers also adds to the sound dampening properties of the door.

Features Acoustic Plus:

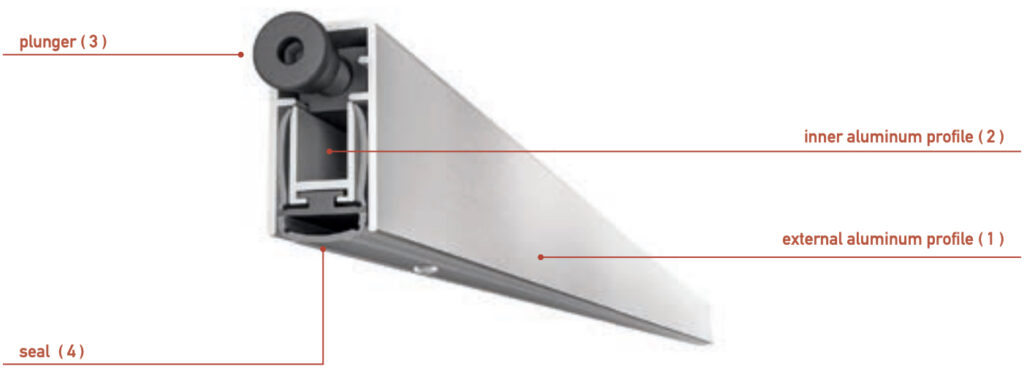

An automatic drop down seal or commonly called draught excluders and are a standard inclusion for the Acoustic range. Keeping draughts of air, smoke, dust and noise out of an environment contributing to greater comfort and guaranteeing savings in terms of the amount of energy required to heat or cool the home.

It is engineered into the door and are automatic devices that drop a seal down to the floor as the door closes. They are activated by a button (plunger) pressed against the door jamb to perfectly seal the gap between the door and floor.

Sound construction

Sound Attenuation Levels:

Coverdoors manufactures Acoustic doors, engaging technologically advanced techniques, single or double leaf with the following sound attenuation levels:

28dB – 33mm tubular chipboard/particle board, light in weight, anti-impact, provides insulation, energy saving and stable in dimension.

Uses: General home

30dB – High density rockwool insulation, 50kg/m2 and thermal insulation with a total thickness of 44mm

Uses: Children’s nurseries, general home

32, 34, 36, 39dB – A unique 3-layer particle board fire rated door blank for 30, 60, 90 and 120 mins, from the certification body IFC, engineered specifically for heavy duty use that also offers excellent performance levels of security, longevity and sound attenuation.

Uses: General offices, schools, home office, hotels, classrooms, recording studios, small music rooms

38dB – Solid 3-layer particle chipboard 3 x 11 VL

Uses: Hospitals, small music rooms, recording studios, theatre rooms.

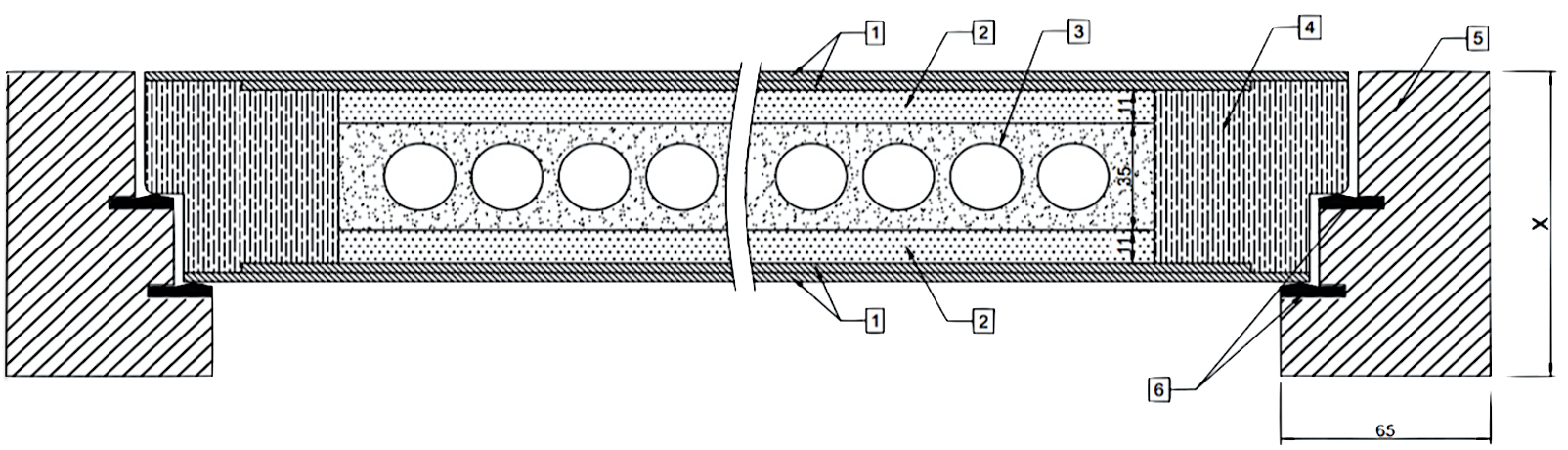

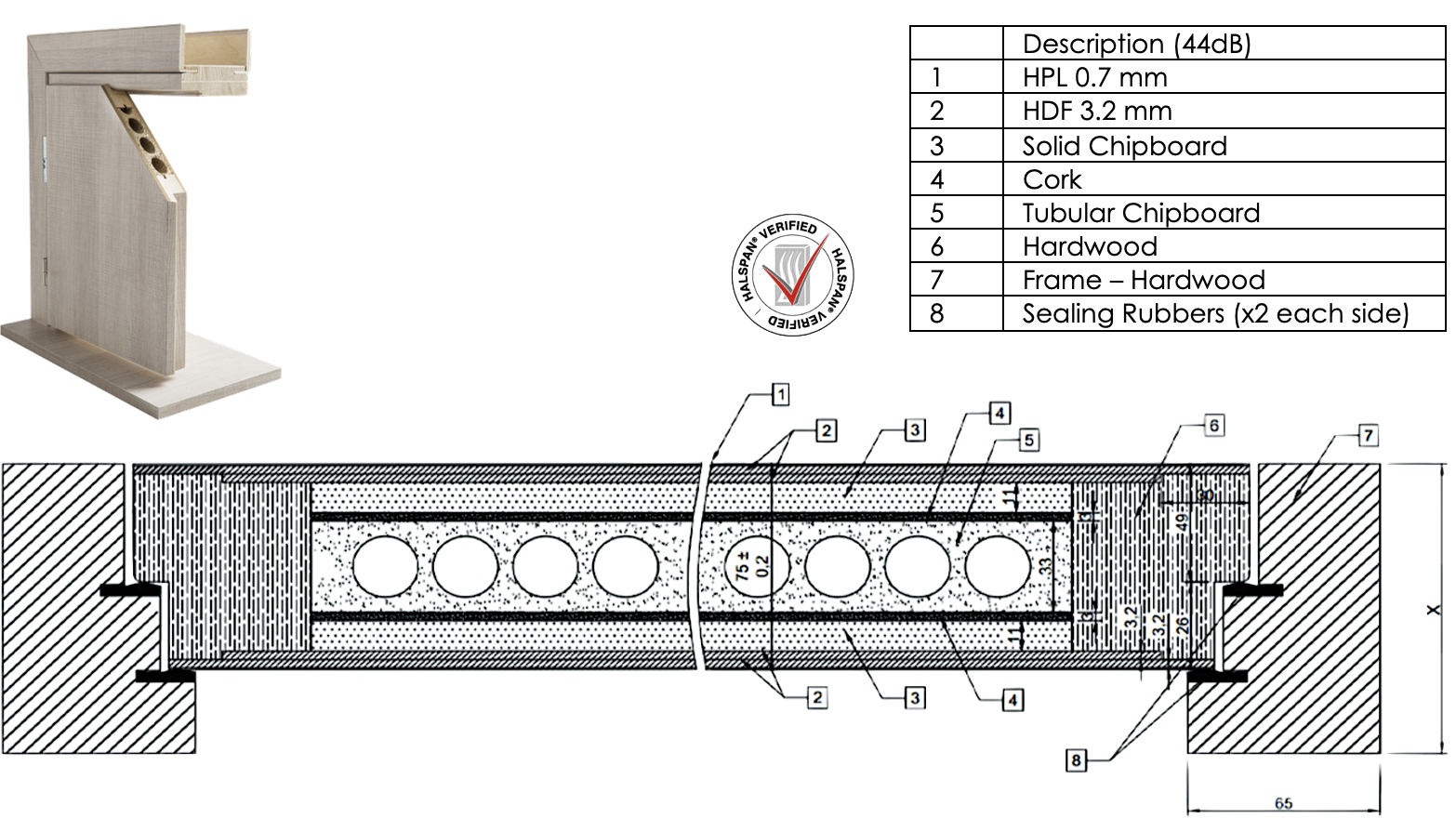

42dB Special sound insulation core

Door leaf – Stiles and rails made of hardwood and covered on both sides with 2 x 3.2 mm HDF

Door core – Consists of tubular chipboard 35mm, solid chipboard 2 x 11mm and cork 2 x 3mm

Door frame – Made of hardwood, double rebated with 2 perimeter rubber seals

Leaf thickness – 70mm

Uses: Large music rooms, conference centres

44dB Special sound insulation core

Door leaf – Stiles and rails made of hardwood and covered on both sides with 2 x 3.2 mm HDF

Door core – Consists of tubular chipboard 35mm, solid chipboard 2 x 11mm and cork 2 x 3mm

Door frame – Made of hardwood, double rebated with 2 perimeter rubber seals

Leaf thickness – 74mm

Uses: Recording studios, concert halls

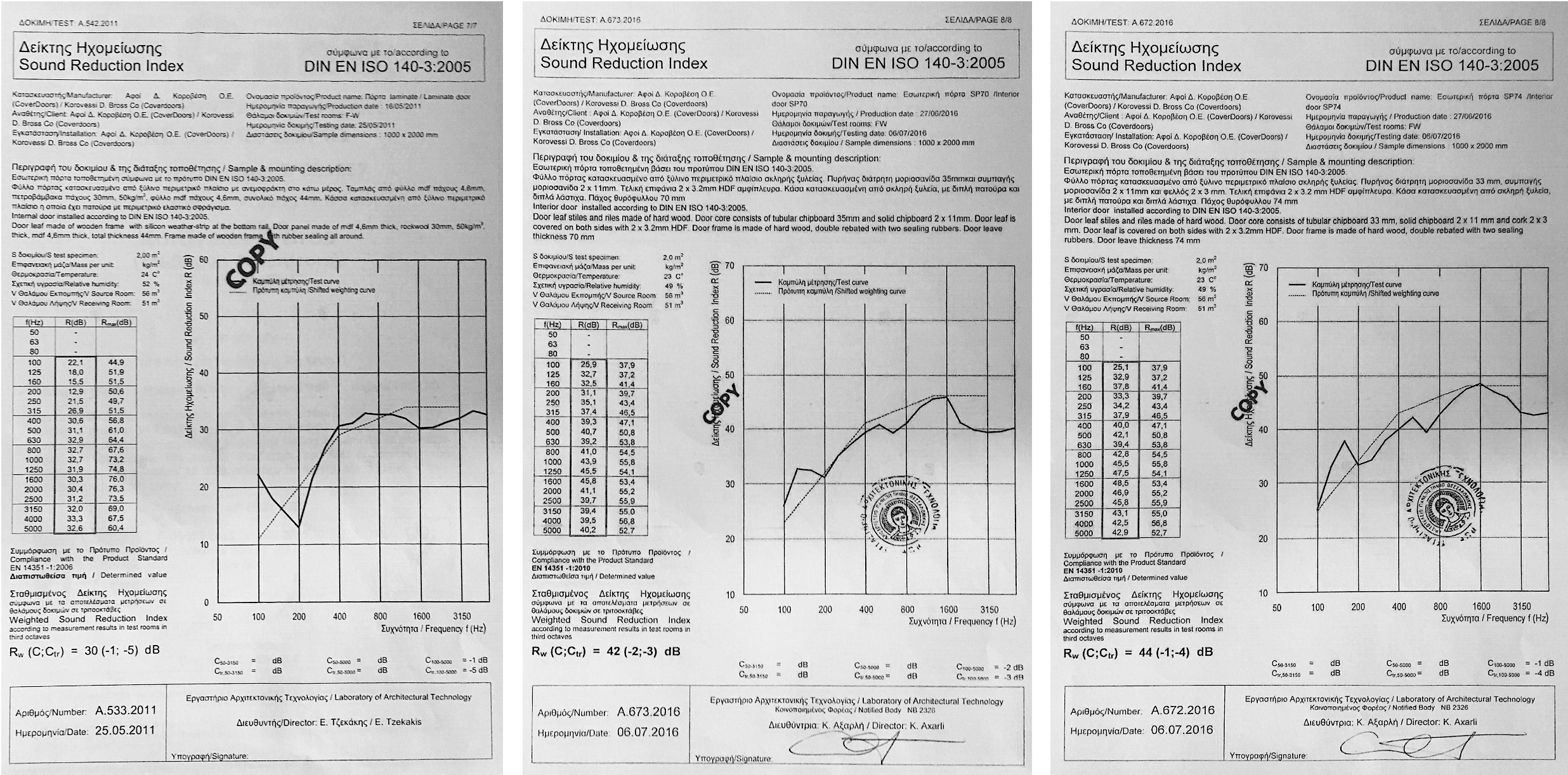

Test Reports

Reviews

There are no reviews yet.